Done.

- Noah

Friday, May 4, 2018

Monday, April 30, 2018

24th, 26th, and 30th

I've been struggling to finish my paper. It's close. I keep telling myself that I can work on it at home or on the weekend, but more imminently important assignments and other extenuating circumstances have prevented me from making as much progress as I've wanted to.

I will be able to finish this week. At this point, thesis takes top priority (which should've happened earlier). I also will probably have secured at least two judges this week. I've contacted a couple of professors at SMU; one responded no, and the other didn't. I also figured that most professors are consumed with EOT testing and things. My best chance for judges are a couple of people that my family and I know.

I won't be able to present this week, but will next week. I'll just have to find a day that I don't have an AP (mon, tues, or fri).

So in summation, I've been adding, editing, and removing from my paper.

- Noah

I will be able to finish this week. At this point, thesis takes top priority (which should've happened earlier). I also will probably have secured at least two judges this week. I've contacted a couple of professors at SMU; one responded no, and the other didn't. I also figured that most professors are consumed with EOT testing and things. My best chance for judges are a couple of people that my family and I know.

I won't be able to present this week, but will next week. I'll just have to find a day that I don't have an AP (mon, tues, or fri).

So in summation, I've been adding, editing, and removing from my paper.

- Noah

Friday, April 20, 2018

Two for one (4/18 + 4/20)!

4/18:

I was granted access to the full "pro" version of the app I use for 3D design, so I now have much more capabilities. (the pro version is usually $300/year, but as a student I can have a free subscription!) I've been toying around with it a lot. I can now import images that I can then sketch construction lines over. I drew an idea that I had for the spinneret in procreate, then imported the JPEG to shapr3D and sketched over the drawing to create a 2D face. What I did then was draw an axis of revolution to revolve the face around. This way, I have a 3D representation of my idea. And now, I can print it out. I am still in the process of refining the design so that there shouldn't be any trouble printing, but also printing different versions for presentation purposes. (I'll insert images when I get home so you can actually see it.)

The printer has also been fixed. The extruder nozzle was cleaned out and we replaced the PLA filament. I think the old one was too old and becoming too brittle to properly feed into the extruder.

So, ultimately, the prototype "spinneret" will be constructed with the following:

Sketching/design: Procreate

3D modeling/refinement: Shapr3D

GC Code/printer programming: Cura

Printer: Monoprice MP Select Mini 3D Printer

Filament: 1.75 mm Black PLA (polylactic acid) by MakerBot

My goal is this weekend to finish my paper and the prototype, so that I can get the paper edited and reviewed next week.

4/20:

Today, I worked on my paper more. Next week, after I finish the rough draft of the paper, I will more actively seek out judges. Or, if I have time, I'll send some emails.

- Noah

I was granted access to the full "pro" version of the app I use for 3D design, so I now have much more capabilities. (the pro version is usually $300/year, but as a student I can have a free subscription!) I've been toying around with it a lot. I can now import images that I can then sketch construction lines over. I drew an idea that I had for the spinneret in procreate, then imported the JPEG to shapr3D and sketched over the drawing to create a 2D face. What I did then was draw an axis of revolution to revolve the face around. This way, I have a 3D representation of my idea. And now, I can print it out. I am still in the process of refining the design so that there shouldn't be any trouble printing, but also printing different versions for presentation purposes. (I'll insert images when I get home so you can actually see it.)

The printer has also been fixed. The extruder nozzle was cleaned out and we replaced the PLA filament. I think the old one was too old and becoming too brittle to properly feed into the extruder.

So, ultimately, the prototype "spinneret" will be constructed with the following:

Sketching/design: Procreate

3D modeling/refinement: Shapr3D

GC Code/printer programming: Cura

Printer: Monoprice MP Select Mini 3D Printer

Filament: 1.75 mm Black PLA (polylactic acid) by MakerBot

My goal is this weekend to finish my paper and the prototype, so that I can get the paper edited and reviewed next week.

4/20:

Today, I worked on my paper more. Next week, after I finish the rough draft of the paper, I will more actively seek out judges. Or, if I have time, I'll send some emails.

- Noah

Monday, April 16, 2018

writing s'more

Today, I wrote a few more pages on my thesis. I wrote about the chemical and physical processes in the formation of native spider silk, the set-up and equipment of the SLU experiment for biomimetic synthesis, and the biomimetic processes involved (both chemical and physical).

Yesterday evening, I went and got more PLA filament for the printer, and hopefully fixed the extruder, so I'll try printing the design I currently have tonight. I also requested free (student) access to the full version of the 3d designing app so that I can have multiple designs, so I don't have to start over each time. Either today or tomorrow it should be granted. Then I can update or modify the design if necessary and reprint.

- Noah

Yesterday evening, I went and got more PLA filament for the printer, and hopefully fixed the extruder, so I'll try printing the design I currently have tonight. I also requested free (student) access to the full version of the 3d designing app so that I can have multiple designs, so I don't have to start over each time. Either today or tomorrow it should be granted. Then I can update or modify the design if necessary and reprint.

- Noah

Sunday, April 15, 2018

April 12th is right here

With the craziness of the power out and STAAR testing, I forgot to post. I was going to write it when I got home thursday, but I forgot. :P

I filled out the form for judges, so hopefully I'll be able to find a couple. My mom (works at UT Southwestern) says there are plenty of grad students at UT southwestern who would probably want to judge 'cause it'll count for service hours. So if she gets a list of students and projects, she can share them with UT Southwestern.

My grandma also worked as a pediatric nurse practitioner who worked with limb recovery patients. One of the applications of my thesis could relate to the medical field, so could my grandma judge (me)...?

I plan on these next coming weeks to finish up my paper and edit it. As for the prototype, hopefully I can print a final version by the end of this week. The only thing I really need to address is the aperture of the spinneret, to get it down to the right size.

- Noah

I filled out the form for judges, so hopefully I'll be able to find a couple. My mom (works at UT Southwestern) says there are plenty of grad students at UT southwestern who would probably want to judge 'cause it'll count for service hours. So if she gets a list of students and projects, she can share them with UT Southwestern.

My grandma also worked as a pediatric nurse practitioner who worked with limb recovery patients. One of the applications of my thesis could relate to the medical field, so could my grandma judge (me)...?

I plan on these next coming weeks to finish up my paper and edit it. As for the prototype, hopefully I can print a final version by the end of this week. The only thing I really need to address is the aperture of the spinneret, to get it down to the right size.

- Noah

Tuesday, April 10, 2018

Finishing the Spinneret Design (maybe)

I’ve been having some trouble with the printer, so I wasn’t able to anything with that.

Today, I started a blueprint and a more final design. I tried a different approach with the designing app. This latest edition has ports where buffer solutions can be introduced into the spinneret, thus creating the desired pH gradient.

I plan on printing a larger version that would be more presentable. The only thing that isn’t quite right about the design is the diameter of the apature, which is too large.

The red arrows indicate the ports for the buffer solutions. The blue arrows indicate the flow of the spidoin protein solution.

I need to get a move on with my paper though, I have about the number of pages required, but it’s not edited at all, and I still have the majority of my actual thesis to write in.

- Noah

Today, I started a blueprint and a more final design. I tried a different approach with the designing app. This latest edition has ports where buffer solutions can be introduced into the spinneret, thus creating the desired pH gradient.

I plan on printing a larger version that would be more presentable. The only thing that isn’t quite right about the design is the diameter of the apature, which is too large.

The red arrows indicate the ports for the buffer solutions. The blue arrows indicate the flow of the spidoin protein solution.

I need to get a move on with my paper though, I have about the number of pages required, but it’s not edited at all, and I still have the majority of my actual thesis to write in.

- Noah

Friday, April 6, 2018

Continuing the paper

Today, I continued working on my paper. This weekend (if not tuesday), I will re-work the design for the spinneret.

I think what I may do is make a scaled-up version (with a cutaway?) and an actual size. This will allow me to show more detail, especially when presenting it, while also making it easier to print.

In my paper, I've divided up the sections, and made smaller sub-sections, so I know exactly what information I'll be putting in my final paper.

My goal for next week is to have the actual-sized model of the spinneret completed. I will then focus on my paper, and work on the larger-scale on the side, so it should be finished in time for the final presentation.

I should have my paper completed within a few weeks so that I can get it checked/corrected. I also need to find some judges!

- Noah

I think what I may do is make a scaled-up version (with a cutaway?) and an actual size. This will allow me to show more detail, especially when presenting it, while also making it easier to print.

In my paper, I've divided up the sections, and made smaller sub-sections, so I know exactly what information I'll be putting in my final paper.

My goal for next week is to have the actual-sized model of the spinneret completed. I will then focus on my paper, and work on the larger-scale on the side, so it should be finished in time for the final presentation.

I should have my paper completed within a few weeks so that I can get it checked/corrected. I also need to find some judges!

- Noah

Monday, April 2, 2018

More troubles...

So a few things to talk about today. I tried printing the latest design again. It didn't work. I ran into a new problem. By the time the printer got to the cylindrical part on top, it was printing fast enough that the top part became a glob of PLA. So, to solve this, I can either slow the printing speed, change the design completely, or make the top larger to give the PLA more time to cool. I'll fix that in the coming days. I'll also need to figure out how it'll be attached to the rest of the device and how to create a pH gradient within it. (?) (PLA is the plastic used to print with; polylactic acid)

Today I worked on my paper and started my final presentation. I laid out the topics I would cover in each of the sections and wrote a short intro paragraph in each. For the presentation, I had the style laid out and all the topics with subtopics.

(I liked the title slide from my last presentation so I'm pretty much keeping it the same.)

- Noah

Today I worked on my paper and started my final presentation. I laid out the topics I would cover in each of the sections and wrote a short intro paragraph in each. For the presentation, I had the style laid out and all the topics with subtopics.

(I liked the title slide from my last presentation so I'm pretty much keeping it the same.)

Wednesday, March 28, 2018

Spinneret Day 2

So I finished a primary design for the spinneret yesterday evening and tried to print it, but the printer I have access to couldn't print all that well-it kept coming off the platform because the supports weren't strong enough.

Today I worked on a new design that would be more printer-friendly.

The small cylinder to the left was the first edition. It was about a centimeter in diameter, but couldn't print well. The new one I did today is to the right of it.

This has a wider base and is a bit larger, so hopefully the printer will be able to handle it.

For scale, the top cylindrical part is about 2cm in diameter. (I also fixed the aperture, it's now about 30 μm in diameter.)

I did something a little different with the internal structure...

Today I worked on a new design that would be more printer-friendly.

The small cylinder to the left was the first edition. It was about a centimeter in diameter, but couldn't print well. The new one I did today is to the right of it.

This has a wider base and is a bit larger, so hopefully the printer will be able to handle it.

For scale, the top cylindrical part is about 2cm in diameter. (I also fixed the aperture, it's now about 30 μm in diameter.)

I did something a little different with the internal structure...

This is more like what I had envisioned for the spinneret. The fluid (dope) comes from the right through a cone that compresses it until it reaches the tube which will do most of the work. Keep in mind, that tube is about 30 millionths a meter in diameter. After passing through the tube, the dope should polymerize and be silk as it exits the spinneret to the left.

I found that such a small structure doesn't even register on the path code for the printer. My final product should be an assembly of the parts I made. As mentioned before, it will not be functional or even tested. I will also include 3D (STL) files of each part in the project, with images such as the one above to illustrate my intentional design.

In the next few days (since we won't be at school friday!) I should work on integrating a method for creating a pH/ion gradient within the spinneret. (I have some ideas.) Hmmm...

- Noah

Monday, March 26, 2018

Beginning the Design Process

I was out last thursday because I was getting my wisdom teeth out (all 4). So please don't murder my grade for missing the thursday blog

Anyways, today I worked on the 3d design of what will be a prototype for a "biomimetic silk spinner." I used a 3d designing app to create a basic form of what the "spinneret" end would look like.

I had to spend a lot of today learning how to use the program, and this is only the beginning. I still need to modify the interior and shape. Here's what I managed to get done today:

Anyways, today I worked on the 3d design of what will be a prototype for a "biomimetic silk spinner." I used a 3d designing app to create a basic form of what the "spinneret" end would look like.

I had to spend a lot of today learning how to use the program, and this is only the beginning. I still need to modify the interior and shape. Here's what I managed to get done today:

You can see in the top screenshot the entire thing. It's about 4cm in diameter. The aperture of the spinneret is however, much smaller. In the second image, you can see a tiny blue dot that is actually a tube that runs the length of the cylinder. It's about 60X10⁻⁶ m in diameter - twice as large as I need it to be. (I just realized I made the radius 30μm instead of the diameter. Crap)

I'll be working on this every so often so that I can have a printed prototype to present in May.

What I need to make sure is that I can construct each piece in a way that I can assemble them. This is the fun part of my project!

- Noah

Tuesday, March 20, 2018

Synthesis

Today, I focused on the physical process of silk synthesis in a laboratory.

The process used in SLU's biomimetic spinning process is as follows:

"Highly concentrated NT2RepCT spinning dope in a syringe is pumped through a pulled-glass capillary with a tip size of 10-30 μm, with the tip submerged into a low-pH aqueous collection bath. Fibers can be taken up from the collection bath and rolled up onto frames."

This method yields fibers 40 μm in diameter (wet; 30 μm capillary). SLU has reported that it has been able to produce strands up to a km in length.

The dope used by SLU (NT2RepCT) is of course a chemical I won't be able to replicate- it is a chimeric protein created by genetically modifying e coli bacteria. However, like in real spiders, they used the dope in a highly concentrated solution, with the concentration interval being 100-500 mg/ml. The low-pH solution that the dope is pumped into should have a pH from 5.5 to 3. That interval supposedly produced the strongest, continuous fibers. pH's lower than 2.5 yielded no fibers, and any pH higher than 6 yielded discontinuous fibers. SLU also varied the diameter of their syringe (which was a custom, pulled-glass capillary), from 10 μm in diameter to 30 μm.

The silk fibers produced in this process are extraordinary, but still not as impressive as nature. "The mechanical characteristics of the fibers were highly reproducible, although the toughness and ultimate tensile strength were lower than native silk. One possible way to increase the toughness could be to spin NT2RepCT fibers with diameters closer to that of native dragline silk, as this apparently has an impact on the mechanical properties of silk fibers."

The SLU report also encouraged that their method can be further developed. It said some examples could be a pH gradient, and an ion composition gradient. This would make their current set-up more like an actual spider, and may result in stronger fibers. I aim to implement such developments in a biomimetic spinning device, along with other things that I may encounter in the future.

The ultimate goal of refining this method is to make artificial spider silk fibers that perform at or above the level of natural spider silk in terms of mechanical properties. And with that, have the process be economically feasible enough that it can be used in an industrial level for mass production of synthetic silk to be used in whatever product/industry necessary.

- Noah

The process used in SLU's biomimetic spinning process is as follows:

"Highly concentrated NT2RepCT spinning dope in a syringe is pumped through a pulled-glass capillary with a tip size of 10-30 μm, with the tip submerged into a low-pH aqueous collection bath. Fibers can be taken up from the collection bath and rolled up onto frames."

This method yields fibers 40 μm in diameter (wet; 30 μm capillary). SLU has reported that it has been able to produce strands up to a km in length.

The dope used by SLU (NT2RepCT) is of course a chemical I won't be able to replicate- it is a chimeric protein created by genetically modifying e coli bacteria. However, like in real spiders, they used the dope in a highly concentrated solution, with the concentration interval being 100-500 mg/ml. The low-pH solution that the dope is pumped into should have a pH from 5.5 to 3. That interval supposedly produced the strongest, continuous fibers. pH's lower than 2.5 yielded no fibers, and any pH higher than 6 yielded discontinuous fibers. SLU also varied the diameter of their syringe (which was a custom, pulled-glass capillary), from 10 μm in diameter to 30 μm.

The silk fibers produced in this process are extraordinary, but still not as impressive as nature. "The mechanical characteristics of the fibers were highly reproducible, although the toughness and ultimate tensile strength were lower than native silk. One possible way to increase the toughness could be to spin NT2RepCT fibers with diameters closer to that of native dragline silk, as this apparently has an impact on the mechanical properties of silk fibers."

The SLU report also encouraged that their method can be further developed. It said some examples could be a pH gradient, and an ion composition gradient. This would make their current set-up more like an actual spider, and may result in stronger fibers. I aim to implement such developments in a biomimetic spinning device, along with other things that I may encounter in the future.

The ultimate goal of refining this method is to make artificial spider silk fibers that perform at or above the level of natural spider silk in terms of mechanical properties. And with that, have the process be economically feasible enough that it can be used in an industrial level for mass production of synthetic silk to be used in whatever product/industry necessary.

- Noah

Saturday, March 17, 2018

Last Wednesday (Junior SAT Day)

I missed last Wednesday, not because I didn't want to write (I had a draft in progress), but because I simply forgot.

I've been out of town this entire spring break, so that's why I'm just now rectifying my mistake.

Anyways, here's what I did:

Because silk has low birefrigence, I may not be able to apply it to as much as I thought I could. I suppose there are still uses with optical materials with low birefrigence, I'll just have to keep looking.

My study on the structure of spider silk should only be a small portion of my final paper, but it'll be an important component nonwithstanding. It'll give me a better understanding of how the silk functions structurally, and how those unique structural properties could be applied in developing new materials, whether they are made to duplicate spider silk or not.

My main focus in my paper will be the applications of spider silk. I figure that here forward, as I begin writing, I should concentrate my research on all potential or possible applications. My looking in to birefrigence, for example, shows that even spider silk has its limits, and it's important that I thoroughly investigate every potential before making any conclusions about it being even feasible.

Now that I've wrapped up structure and some resulting properties, I'll look at deconstructing SLU's process step-by-step, so that I can first write about it, but then also apply that to the designing of my "biomimetic silk spinner." I may not even have a physical model finished/prepared, but it'll be an interesting synthesis of what I've learned.

I've been out of town this entire spring break, so that's why I'm just now rectifying my mistake.

Anyways, here's what I did:

Because silk has low birefrigence, I may not be able to apply it to as much as I thought I could. I suppose there are still uses with optical materials with low birefrigence, I'll just have to keep looking.

My study on the structure of spider silk should only be a small portion of my final paper, but it'll be an important component nonwithstanding. It'll give me a better understanding of how the silk functions structurally, and how those unique structural properties could be applied in developing new materials, whether they are made to duplicate spider silk or not.

My main focus in my paper will be the applications of spider silk. I figure that here forward, as I begin writing, I should concentrate my research on all potential or possible applications. My looking in to birefrigence, for example, shows that even spider silk has its limits, and it's important that I thoroughly investigate every potential before making any conclusions about it being even feasible.

Now that I've wrapped up structure and some resulting properties, I'll look at deconstructing SLU's process step-by-step, so that I can first write about it, but then also apply that to the designing of my "biomimetic silk spinner." I may not even have a physical model finished/prepared, but it'll be an interesting synthesis of what I've learned.

Monday, March 5, 2018

I start my paper...

Today, I really wasn't able to do much research, we just reviewed the guidelines for our final thesis paper and presentation.

I began my final paper. I formatted the title page, made a table of contents, and have all of the topics/subjects I will cover planned out. Hopefully, each week I can finish (mostly) each section, so that I'll be finished in plenty of time to get it reviewed, corrected, etc. Plus, it'll be nice to be done with.

I should also probably start looking for judges.

- Noah

I began my final paper. I formatted the title page, made a table of contents, and have all of the topics/subjects I will cover planned out. Hopefully, each week I can finish (mostly) each section, so that I'll be finished in plenty of time to get it reviewed, corrected, etc. Plus, it'll be nice to be done with.

I should also probably start looking for judges.

- Noah

Thursday, March 1, 2018

Today, I looked at the primary and secondary structure of spider silk.

Side note, apparently spider silk has low birefrigence. Now this actually is okay, because you don't want the index of refraction to change much if used in fiber optics. And, because it's already been used/planned to be used in molecule detection, it's been proven to be applicable there.

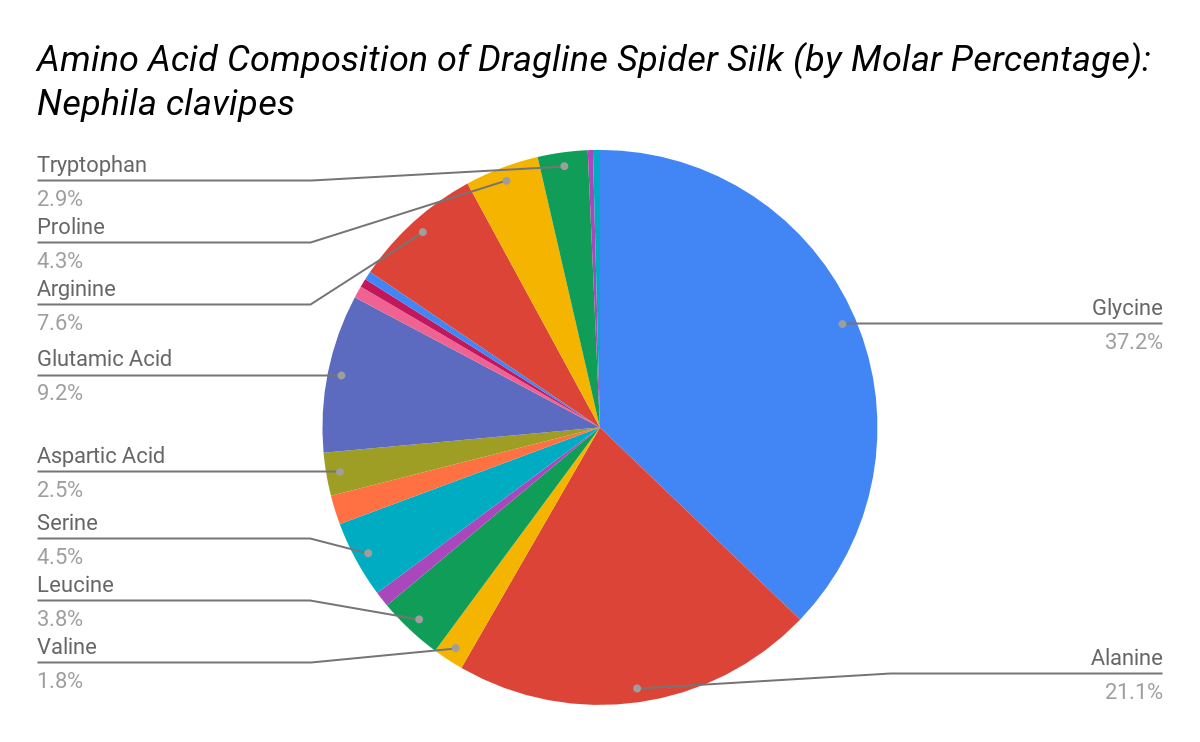

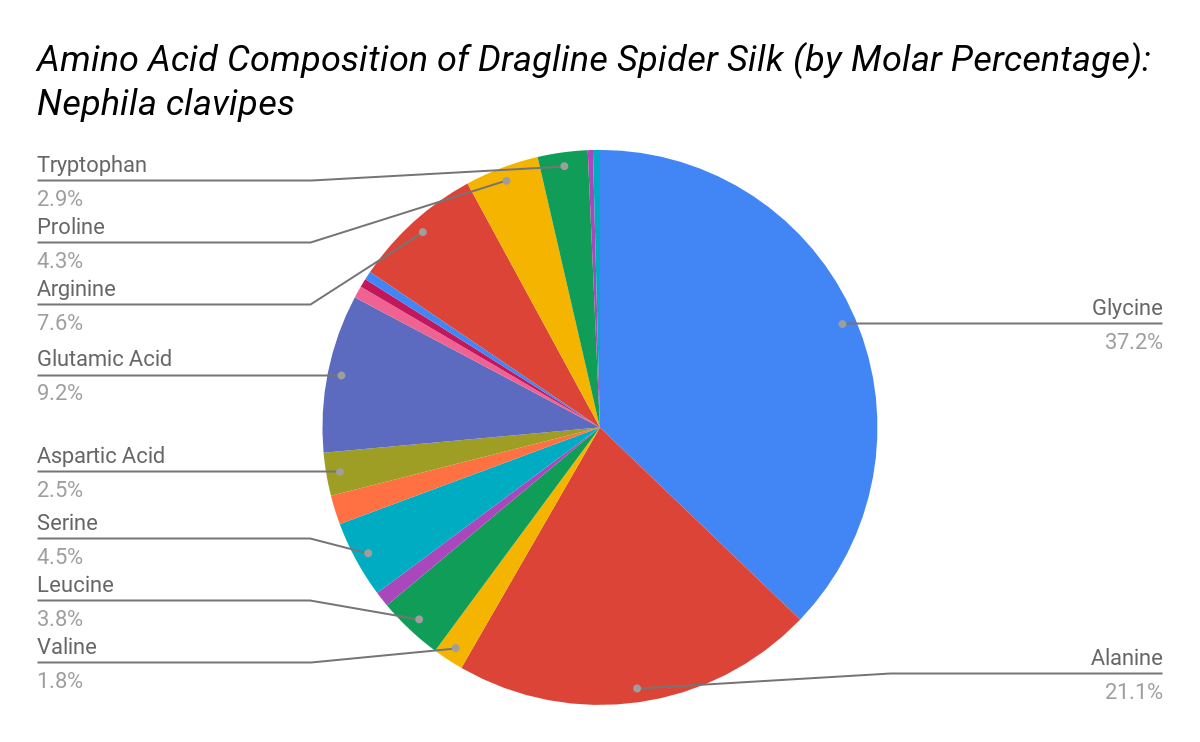

Okay, now, structure. Primary structure is fairly simple and I discussed it some in my presentation. Primary structure of spider silk is mainly (90%) repetitive amino acid sequences. Most of these amino acids are glycine and alanine. This chart I made shows the molar %. --->

Okay, now, structure. Primary structure is fairly simple and I discussed it some in my presentation. Primary structure of spider silk is mainly (90%) repetitive amino acid sequences. Most of these amino acids are glycine and alanine. This chart I made shows the molar %. --->

"Structural analysis revealed that oligopeptides with the sequence (GA)n/(A)n tend to form α-helices in solution and β-sheet structures in assembled fibers." This allows for the elasticity of spider silk. ( A β-sheet looks like a piece of paper that's been creased along the length so it looks like... nevermind, here's a picture: --->) So when stress is applied, the protein will stretch ("straighten out"...?) instead of breaking. The repetitive protein sequences is also crucial to its tensile strength.

However, at the terminals (ends) of the protein, there are nonrepetitive proteins. These are crucial for protein assembly because they form intermolecular bonds that stabilize dimers (2+ monomers), etc. during the "assembly."

However, at the terminals (ends) of the protein, there are nonrepetitive proteins. These are crucial for protein assembly because they form intermolecular bonds that stabilize dimers (2+ monomers), etc. during the "assembly."

At a more macroscopic level, spider silk looks more like a rope that's coated in a protective "skin." In this diagram, you can see the macroscopic view with a diameter of 1-50𝜇m (1𝜇m = 1x10⁻⁶m). Then there are subunits (diameter of 2nm and average length of 7nm. 1nm = 1x10⁻⁹ m) which are comprised of the repetitive amino acid sequences which form the β-sheet structures (in blue).

We still don't fully understand the entire structure and functions within the spider silk. It's probably one of the most complicated structures we know of. But it's also fascinating, so I will do all that I can to learn as much as I can about the structure, at least enough to present my thesis, which I think I've surpassed already. (At least I'll have plenty to write about.)

So what I know right now isn't even scratching the surface of the current understanding, and there's no way I will know as much as we know, that would take years. Really, as long as I have a fundamental understanding of how the structure works, how it changes during fiber formation, and how the structure gives silk its properties, I'll be set. Next week, I'll focus on tertiary and quarternary structure, and begin looking at making a step by step journey through silk synthesis in nature, so that I can compare it to laboratory methods later.

- Noah

Side note, apparently spider silk has low birefrigence. Now this actually is okay, because you don't want the index of refraction to change much if used in fiber optics. And, because it's already been used/planned to be used in molecule detection, it's been proven to be applicable there.

"Structural analysis revealed that oligopeptides with the sequence (GA)n/(A)n tend to form α-helices in solution and β-sheet structures in assembled fibers." This allows for the elasticity of spider silk. ( A β-sheet looks like a piece of paper that's been creased along the length so it looks like... nevermind, here's a picture: --->) So when stress is applied, the protein will stretch ("straighten out"...?) instead of breaking. The repetitive protein sequences is also crucial to its tensile strength.

However, at the terminals (ends) of the protein, there are nonrepetitive proteins. These are crucial for protein assembly because they form intermolecular bonds that stabilize dimers (2+ monomers), etc. during the "assembly."

However, at the terminals (ends) of the protein, there are nonrepetitive proteins. These are crucial for protein assembly because they form intermolecular bonds that stabilize dimers (2+ monomers), etc. during the "assembly." At a more macroscopic level, spider silk looks more like a rope that's coated in a protective "skin." In this diagram, you can see the macroscopic view with a diameter of 1-50𝜇m (1𝜇m = 1x10⁻⁶m). Then there are subunits (diameter of 2nm and average length of 7nm. 1nm = 1x10⁻⁹ m) which are comprised of the repetitive amino acid sequences which form the β-sheet structures (in blue).

We still don't fully understand the entire structure and functions within the spider silk. It's probably one of the most complicated structures we know of. But it's also fascinating, so I will do all that I can to learn as much as I can about the structure, at least enough to present my thesis, which I think I've surpassed already. (At least I'll have plenty to write about.)

So what I know right now isn't even scratching the surface of the current understanding, and there's no way I will know as much as we know, that would take years. Really, as long as I have a fundamental understanding of how the structure works, how it changes during fiber formation, and how the structure gives silk its properties, I'll be set. Next week, I'll focus on tertiary and quarternary structure, and begin looking at making a step by step journey through silk synthesis in nature, so that I can compare it to laboratory methods later.

- Noah

Tuesday, February 27, 2018

Birefringence of Spider Silk

As planned last week, today I investigated the birefringence of spider silk and its possible applicability in medical technology, etc.

First off, let me explain birefringence. It's the property of a substance where the index of refraction changes based on the polarization and direction of propagation of light.

Where λ is one wavelength. (Note how E oscillates in the x direction and B in the y.)

Okay, so birefringent substances change their index of refraction as the orientation and direction of light changes.

This means that the speed of light through the substance is no longer constant. And if we wanted to know the index of refraction we'd need some math. (This is really simple, but just to get an idea of what's happening. There's a bunch of del's and multivariable calculus in the actual theory.)

We'll say that the index of refraction (n) is equal to v/c. But this time, v will be a function of x, a function of position of a substance on the x axis.

n = v(x) / c

Now, the index is dependent on where you are in the substance.

So what can you do with a birefringent substance?

Some researchers in EPFL's group for Fibre Optics believe that spider silk could potentially be used in chemical detection. Because of the way it can conduct light, they think it could be useful in medical devices to be implanted in a living body. This is also possible because silk is biodegradable.

Birefringence is also used to diagnose diseases, but silk doesn't have an application there. Next time, I will probably look more at applications, and then move on to the different levels/domains of silk's structure.

Friday, February 23, 2018

Time to catch up

I haven't posted in about a week, so this is to account both for this week (which was really one day because I was absent Wednesday) and last week.

I been mostly looking at the optical properties of spider silk. As I discussed among the many applications of spider silk was the possibility of using it in place of fiber optic cable (FOC). At the time of my presentation, I had yet to learn more about it since I was looking in to other things. I have now been investigating this. What I have found so far is very promising.

First let me explain the index of refraction. The index of refraction is defined as:

n ≡ c/v

where n is the index, c is the speed of light in a vacuum, and v is the speed of light through a particular substance. The index of space is obviously 1, and air is very close to that. Normal FOC typically has an index of about 1.44 which is pretty good. There is only about a 31% decrease in the speed of light, which is still ridiculously fast. (~2.083X10⁸ m/s)

Now, spider silk has been found to have an index of about 1.55. That's still good, but not as good as FOC. Spider silk reduces the speed of light by ~36%. So, between FOC and spider silk, there's only a 5% difference in speed. While it would take light traveling the distance to the moon 1.85 seconds through FOC, it would take 1.98 seconds through spider silk. So the question I have to answer now is: is it worth it to reduce the speed?

FOC typically has a diameter of 50 microns (50 millionths of a meter) not including the layers of insulation and protection around it. Spider silk has a diameter close to 7 microns. This means that you have more channels to transport information in the same space, ~7 times as much.

Also I've considered too the production of FOC vs. silk in making it available for common and universal use. FOC can now be made at 50 m/s. Silk likely can't compete with that speed. At best, you can only produce a few meters per second.

The process of manufacturing FOC is a very complex process that involves chemical vapor deposition, drawing, and coating. The manufacturing of spider silk is also complex, as discussed in my presentation. However, silk has no bi-products and the lab setup is simple.

FOC also has some practical issues. It's glass, so it's not nearly flexible as silk. It also has issues with installation because of its maximum tensile strength.

Thinking holistically, you have to make the best use of time, resources, money, and space for this to be a feasible option. Spider silk as a product itself would reduce the normal speed by 5% and is manufactured at a slower rate. However, it is smaller in diameter, is cheaper to make, is clean, and more durable.

Of course I may be biased because this is my thesis and I want silk to be used anywhere possible, but I think silk could be a viable alternative to fiber optic cable despite any cons. I will continue to investigate this one application as I move on to others.

Next week, I'll look at applications based on its birefringence.

Birefringence is the property of a material where the index of refraction changes based on the polarization and propagation direction of light. Think liquid crystal displays in alarm clocks. The display changes as you angle it away or towards you. This property is made use of in numerous medical instruments etc.

Should be interesting...

- Noah

Thursday, February 8, 2018

Back in the swing

Today, since we finished all the presentations, I went back to working on my thesis.

the feedback that I got for my presentation was helpful, and I'll use it for next time.

So, today I took a closer look at the quaternary structure of the proteins (in aqueous solution anyway). Apparently it doesn't have any "considerable" secondary or tertiary structure. "Particularly in their repetitive core domains, however, the long repetitive sequences permit weak but numerous intra- and intermolecular interactions between neighboring domains and proteins upon passage through the spinning duct." And it's because of these interactions through the extrusion, that the secondary through tertiary structures emerge as the proteins polymerize.

Cool stuff.

Also, "the high electron density regions comprise crystalline sub-structures with high β-sheet content.39 These sub-structures are thought to be responsible for the mechanical strength of the silk thread. The elasticity of silk is based on the areas with low electron density, which are characterized by amorphous structures with few defined elements of secondary or supersecondary structure.40,41 Such arrangement closely resembles that of protein hydrogels.42 Upon tensile loading, the hydrogel-like areas can partially deform, contributing to the elasticity and flexibility of the thread."

This gives me a better understanding of the chemical/physical reasons for the rigidity/elasticity.

I'm really enjoying this topic, and I can't wait to present my finished project! I should probably start that paper soon...

All in a day's work,

- Noah

the feedback that I got for my presentation was helpful, and I'll use it for next time.

So, today I took a closer look at the quaternary structure of the proteins (in aqueous solution anyway). Apparently it doesn't have any "considerable" secondary or tertiary structure. "Particularly in their repetitive core domains, however, the long repetitive sequences permit weak but numerous intra- and intermolecular interactions between neighboring domains and proteins upon passage through the spinning duct." And it's because of these interactions through the extrusion, that the secondary through tertiary structures emerge as the proteins polymerize.

Cool stuff.

Also, "the high electron density regions comprise crystalline sub-structures with high β-sheet content.39 These sub-structures are thought to be responsible for the mechanical strength of the silk thread. The elasticity of silk is based on the areas with low electron density, which are characterized by amorphous structures with few defined elements of secondary or supersecondary structure.40,41 Such arrangement closely resembles that of protein hydrogels.42 Upon tensile loading, the hydrogel-like areas can partially deform, contributing to the elasticity and flexibility of the thread."

This gives me a better understanding of the chemical/physical reasons for the rigidity/elasticity.

I'm really enjoying this topic, and I can't wait to present my finished project! I should probably start that paper soon...

All in a day's work,

- Noah

Friday, January 26, 2018

Thesis (non-presentation day)

Thursday we didn't present. I prepped for my presentation Monday. I couldn't post yesterday 'cause of the stupid wifi, so that threw me off my blog routine.

Quick spoiler:

Spider silk can be coated with gold or carbon nanotubes to become an excellent conductor of electricity, and it's only a small fraction of the width of human hair. This has major implications for everything involving electronics. (which is essentially, a lot of things.) You can make circuits and therefore devices much, much, much smaller.

So ya, that's pretty significant application...

Can you imagine the implications of being able to implement this into every technology?! You can make computers the same size they are now, but several times more powerful. More technologies could become possible. Remember before the first integrated circuit? The IC changed modern technology. With such a universal improvement, this could be big.

In my presentation, I plan to explore this and several other potential applications that would revolutionize modern life and technology.

- Noah

Quick spoiler:

Spider silk can be coated with gold or carbon nanotubes to become an excellent conductor of electricity, and it's only a small fraction of the width of human hair. This has major implications for everything involving electronics. (which is essentially, a lot of things.) You can make circuits and therefore devices much, much, much smaller.

So ya, that's pretty significant application...

Can you imagine the implications of being able to implement this into every technology?! You can make computers the same size they are now, but several times more powerful. More technologies could become possible. Remember before the first integrated circuit? The IC changed modern technology. With such a universal improvement, this could be big.

In my presentation, I plan to explore this and several other potential applications that would revolutionize modern life and technology.

- Noah

Tuesday, January 23, 2018

Thesis Presentations Day 1

Today we listened to presentations. I took notes, made comments, etc. Honestly disappointed I won't be presenting Thursday.

- Noah

- Noah

Friday, January 19, 2018

Thesis work day - chemical analysis

Today I worked on learning more about silk structure, more specifically chemical composition.

I also created a nifty pie chart that easily visualizes how much of the protein is made from glycine and alanine.

I will definitely be ready for my presentation.

- Noah

I also created a nifty pie chart that easily visualizes how much of the protein is made from glycine and alanine.

I will definitely be ready for my presentation.

- Noah

Wednesday, January 17, 2018

Thesis Presentation work day 2

Today I primarily worked on the "Potential Applications and Uses" section of my presentation. It's the main focus of my thesis and should serve as an adequate "wow" factor. I won't show the slide so I won't spoil it.

Here's a different slide though:

Noah

Here's a different slide though:

Noah

Friday, January 12, 2018

Presentation Preparation

Today I worked the entire period on my presentation that will happen in a couple of weeks. I decided to go ahead and work on it. I actually got into it, I didn't realize I had spent an hour and a half preparing this presentation. I'm mostly done, I just need to put in more information and practice presenting it.

This is my first slide:

Hopefully, it'll be a cool presentation.

- Noah

This is my first slide:

Hopefully, it'll be a cool presentation.

- Noah

Wednesday, January 10, 2018

First Day Back (After Winter Break)

After two weeks off, it's good to be back in school. I'm excited for E&M and learning more about the mathematics of integrals in calculus.

Today in thesis, I worked on organizing what information I will be presenting and synthesizing from. I focused on my first topic: Structure and Resulting Properties. I found multiple new authoritative resources specific to this topic. Over the next few weeks, I will be progressing through my topics and eventually will craft a paper that will present what I have learned. I can also at that time begin preparing how I will deliver my presentation. I might also like to know what professions the judges will be. Because my topic is so specific, I'm not sure how familiar they might be with it; this will influence how I present my information and research.

- Noah

Today in thesis, I worked on organizing what information I will be presenting and synthesizing from. I focused on my first topic: Structure and Resulting Properties. I found multiple new authoritative resources specific to this topic. Over the next few weeks, I will be progressing through my topics and eventually will craft a paper that will present what I have learned. I can also at that time begin preparing how I will deliver my presentation. I might also like to know what professions the judges will be. Because my topic is so specific, I'm not sure how familiar they might be with it; this will influence how I present my information and research.

Structure and Resulting Properties

Spider silk exists as a chain of proteins, a polymer, with varying and repeating structures that give it both rigidity and elasticity. It exists as 𝛽-sheets that form helices (𝛼-helices in solution). “Amyloid fibrils share similarities with 𝛽-sheets of spider silk and have been observed in the distal third of the spinning duct by electron microscopy (EM), and it was proposed that the spidroin repetitive parts are responsible for the amyloidogenic behavior.” (“Carbonic Anhydrase…” pg 3) Rich in glycine and alanine residues.

𝛽-sheets allow for the mechanical/tensile strength of spider silk

Macroscopic Structure:

Essentially, silk exists as a layered cord with an external crystalline “skin” that covers an internal structure of polypeptides. This skin protects the integrity of the inside while also allowing the silk to be antimicrobial. The inside can best be described as 𝛽-sheets, covalently connected, suspended in an amorphous “gel.”(?)

Outer Layer and Shock/Energy Absorption: “Outer layers of Nephila madagascariensis show a thin peripheral layer [of skin] with elongated cavities...oriented parallel to silk fiber axis. These domains act as stress concentration points, crack initiators that inhibit the spreading of the cracks by delaying the rupture of the fiber by taking up the energy. The inhibition effect of these domains arise from self repairing of cracks by solidification under high stress areas, plasticizing effect by hydration to act as fluid shock absorbers, and act as a lubricant to reduce the inter[-]fibrillar friction.” (3. Pg 8)

“Under tension, the glycine-rich sequences are able to perform large-scale beta sheet crystal structures that are less perfectly ordered than polyalanine crystals.” (3. Pg 8)

Optical Properties (Birefringence): “The birefringence of Nephila clavipes liquid protein is low to the extent of .01 to .002 and the contribution of form birefringence to the total birefringence of the fiber has been found to be more significant.” (3. Pg 9)

Thermal Properties:

Y (Thermal expansion coefficient) = -10.6 x 10⁻⁴ ℃⁻¹

“...fibers are thermally stable up to 230℃.” (3. Pg 11)

Electrical Properties:

Spider silk is not piezoelectric.

Fine Structure:

Spider silk has both amorphous (oriented and non-oriented) and crystalline regions.

Primary-

Secondary-

Tertiary-

Quaternary-

References:

5. https://pdfs.semanticscholar.org/2bce/53b60ac449ff10401a87a4a8e9994c465b96.pdf - DNA/Protein seq.

Synthesis: The Chemical and Physical Processes

Replication in a Laboratory for Biomimetic Synthesis

Designing and Constructing a Theoretical “Biomimetic Silk Spinner”

Potential Applications and Uses

References:

- Noah

Subscribe to:

Posts (Atom)